Reduced heating time to 1/2.5, cooling time to 1/4 (compared with conventional company products), horizontal air flow appropriate for loaded operation, the standard oven for production lines supporting multi power supplies. The product lineup includes a silicon free type.

Features

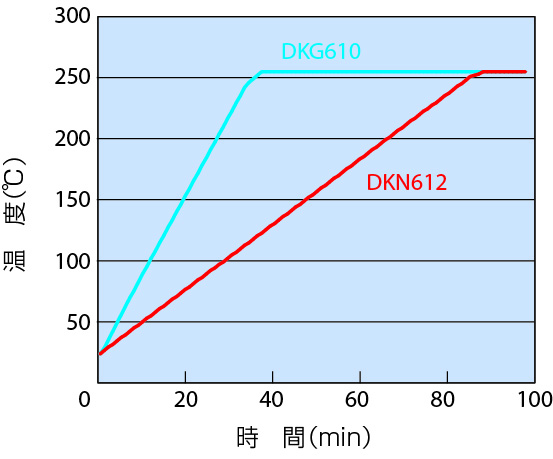

Standard oven with simple operation whose temperature increase and decrease time has been improved 50% or more compared with conventional products to reduce product takt time.

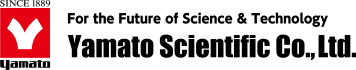

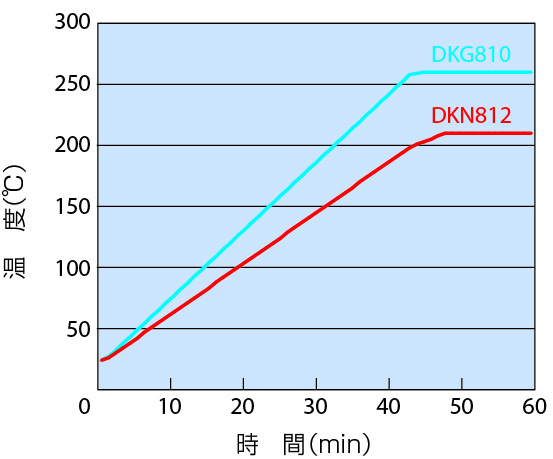

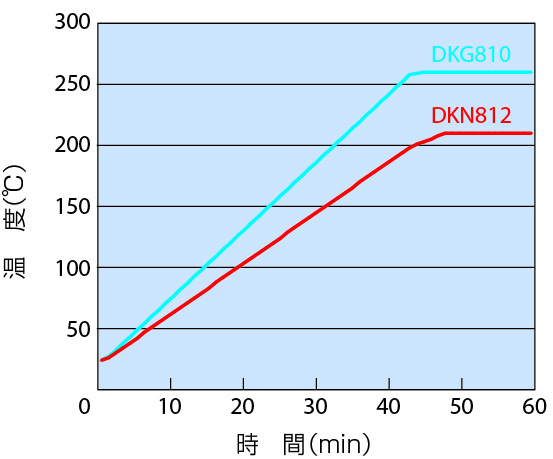

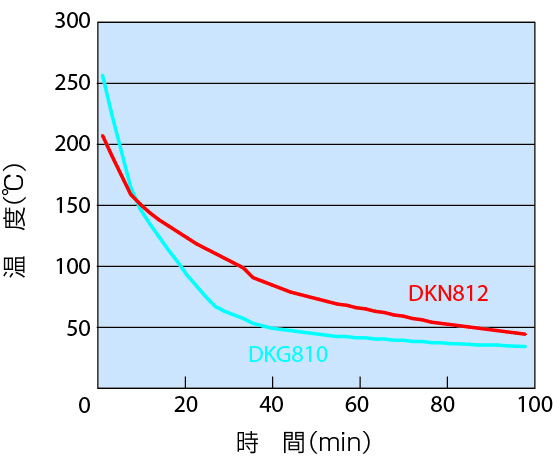

Temperature increase time has been reduced up to 1/2.5 (at no load, compared with conventional company products), temperature decrease time has also been reduced to 1/4 (at no load, compared with conventional company products). Extensive increase in work efficiency is expected.

Employment of a total exhaust system in which air supply and discharge are linked by operation of the manual damper at the front realizes extensive reduction in temperature decrease time.

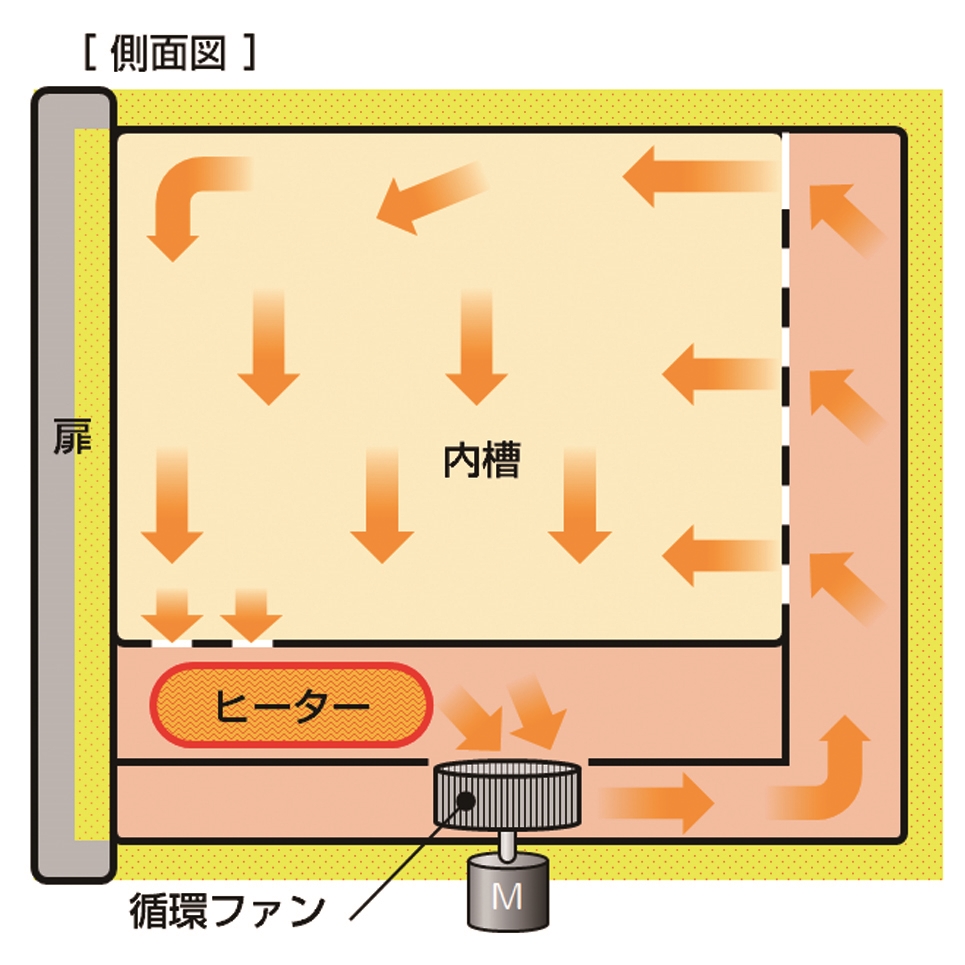

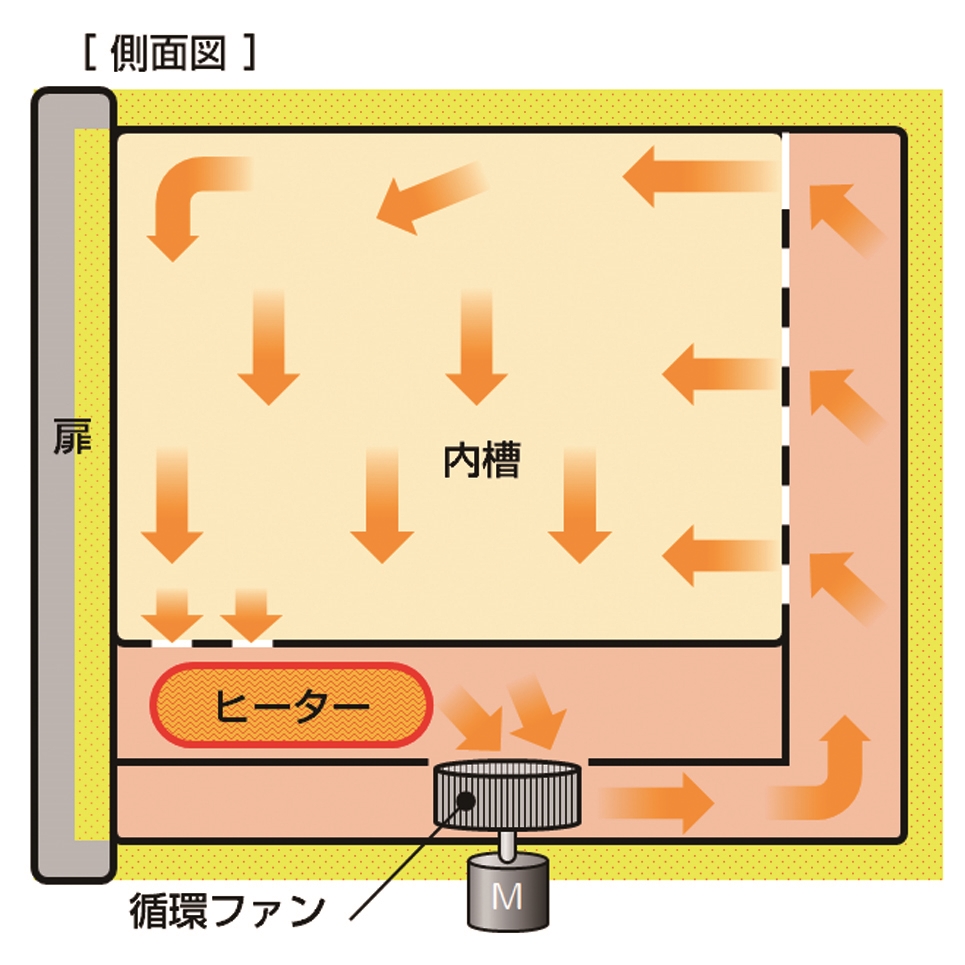

The horizontal air flow system ideal for processing samples in a magazine rack or a lot of samples realizes high precision temperature performance even at loaded condition.

Fluoro rubber is employed for shoulder packing to realize silicon free. (DKG610V/650V/810V/850V)

Product lineup includes 610/610V/810/810V for 200 to 220V power supply and 650/650V/850/850V for 230 to 300L 240V to support multiple power supplies.

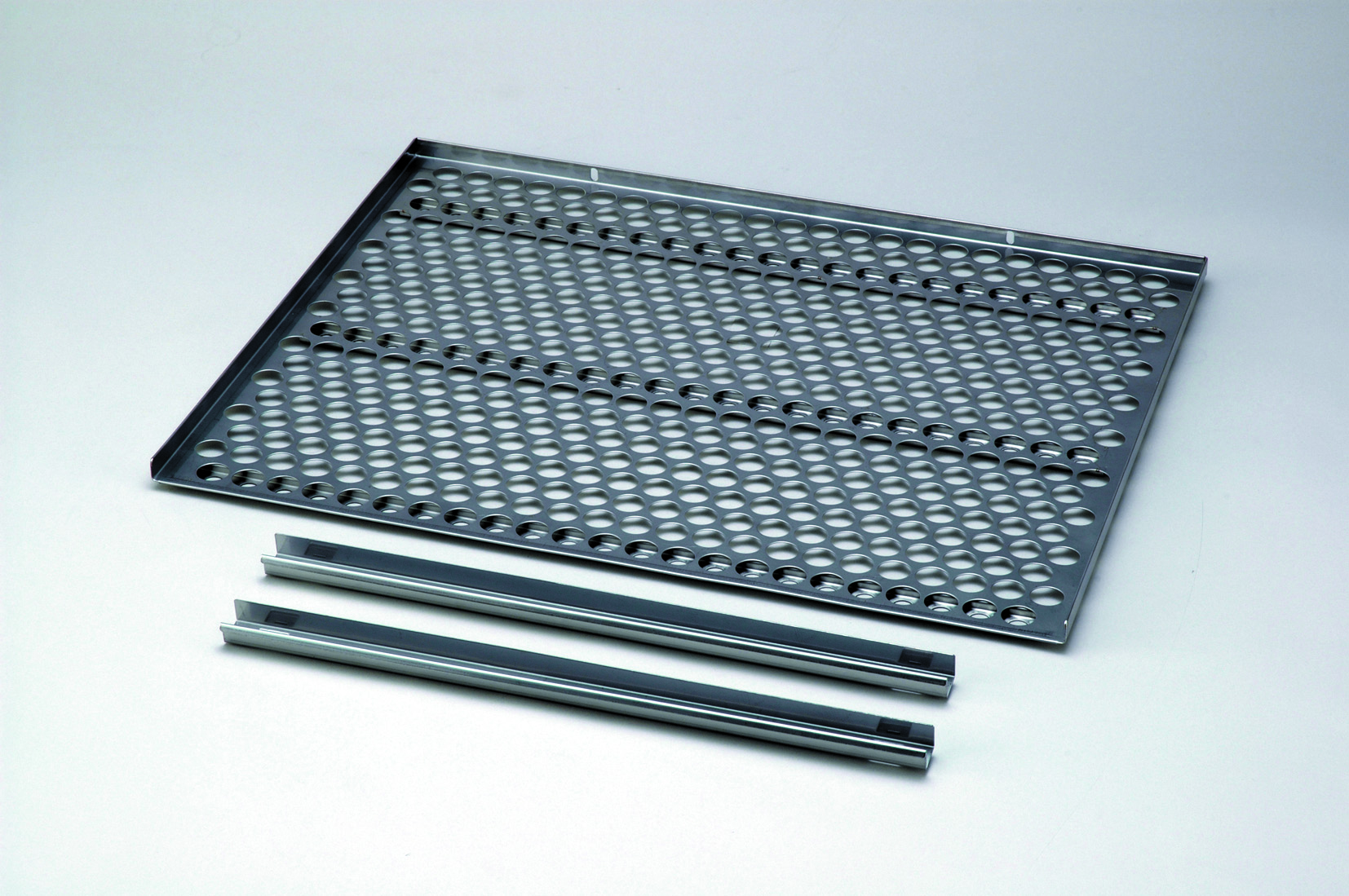

Stainless punching metal shelf()

Cable port(ODK22-1)

Cable port(ODK23-1)

Stand(ON62)

Temperature output terminal (4-20 mA)(ODK24-1)

External communication function (RS485)(ODK25-1)

External communication adapter(O281563)

Independent overheat prevention device(ODK27-1)

Automatic damper(for DKG)

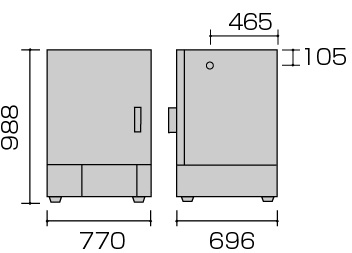

Industrial Forced Convection Oven (Silicorn/Fluoro-rubber Gasket)(DKG650)

Industrial Forced Convection Oven (Silicorn/Fluoro-rubber Gasket)(DKG650V)

Industrial Forced Convection Oven (Silicorn/Fluoro-rubber Gasket)(DKG610V)

Industrial Forced Convection Oven (Silicorn/Fluoro-rubber Gasket)(DKG810V)

Industrial Forced Convection Oven (Silicorn/Fluoro-rubber Gasket)(DKG811V)